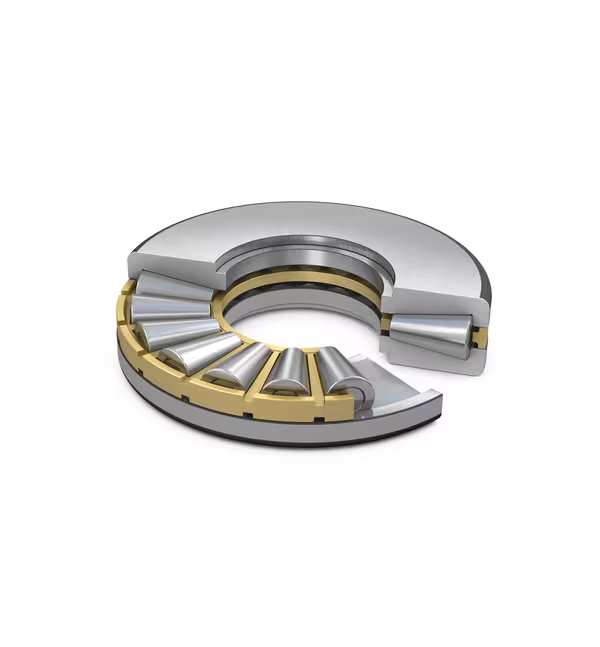

Brief Introduction

A thrust bearing is a type of bearing designed to handle axial loads, or forces that act parallel to the axis of rotation. Unlike radial bearings that primarily support perpendicular forces (perpendicular to the shaft), thrust bearings are specifically engineered to manage axial loads by providing low friction and facilitating smooth rotation. They are crucial components in various mechanical systems such as engines, turbines, pumps, and gearboxes, where they ensure efficient operation and help maintain the integrity of rotating shafts under axial forces. Thrust bearings come in different designs, including ball thrust bearings, roller thrust bearings, and fluid thrust bearings, each suited for different load capacities and operating conditions.

Marine Applications

Propulsion systems in ships and submarines rely on thrust bearings to support axial loads generated by propeller shafts.

Industrial Machinery

Various types of industrial machinery, such as pumps, compressors, and machine tools, use thrust bearings to support axial loads generated by rotating shafts and components.

Wind Turbines

Thrust bearings support axial loads in wind turbine gearboxes, where they ensure smooth operation and reliability of the turbine.

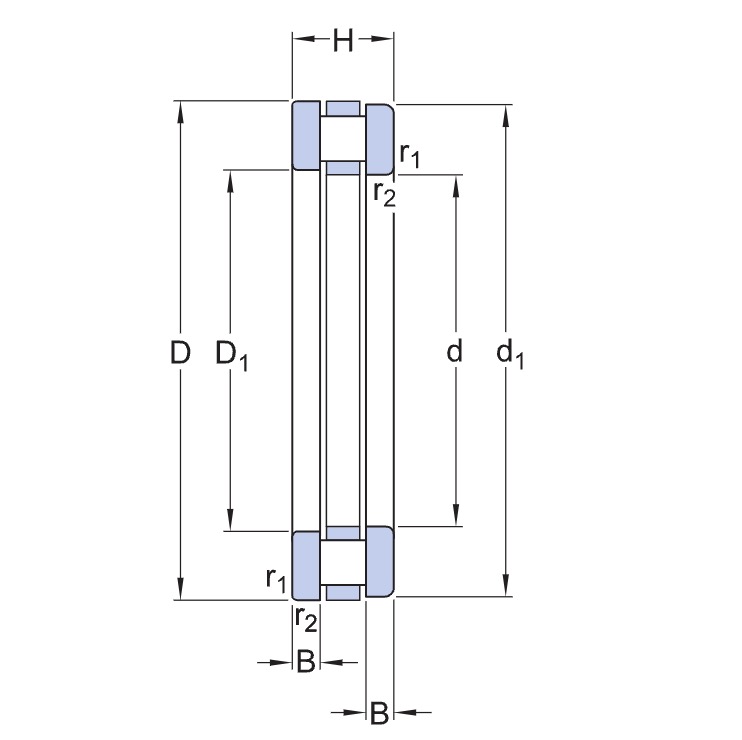

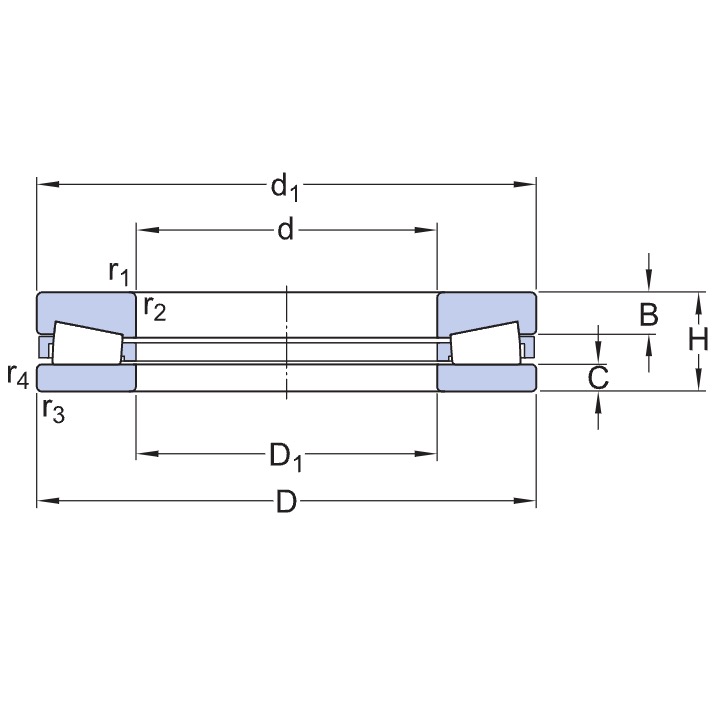

Product Drawing

Advantages of Thrust Bearings

Axial Load Support: Thrust bearings are specifically designed to support axial loads, which are forces acting parallel to the axis of rotation. They effectively handle these loads without significant wear or damage to other components.

Compact Design: Thrust bearings are typically compact and lightweight, which allows for efficient use of space in mechanical assemblies. This is advantageous in applications where size and weight are critical factors.

Low Friction: Thrust bearings are engineered to minimize friction between moving parts. This characteristic reduces energy consumption and heat generation, contributing to overall efficiency and longevity of the machinery.

Versatility: They are available in various designs (such as ball thrust bearings, roller thrust bearings, and fluid thrust bearings) to accommodate different load capacities, speeds, and operating conditions. This versatility allows for customization based on specific application requirements.

How to test a good-quality thrust bearing ?

Tips…

Visual Inspection

Start with a visual examination of the bearing for any signs of damage, wear, or irregularities in its components, such as balls or rollers, cages, and raceways. Look for smooth surfaces and consistent dimensions.

Dimensional Checks

Measure critical dimensions such as bore diameter, outside diameter, width, and overall height using precision instruments. Compare these dimensions against manufacturer specifications to ensure they meet tolerances.

Load Capacity Testing

Apply axial loads to the bearing using a testing machine or fixture designed for this purpose. Measure the load capacity and determine the maximum load the bearing can withstand without permanent deformation or failure.

Rotational Testing

Rotate the bearing at specified speeds to simulate operational conditions. Monitor for smooth rotation, minimal noise, and absence of vibration, which indicate good quality and proper lubrication.

Friction Testing

Measure the frictional torque or force required to rotate the bearing under load. Lower friction indicates better efficiency and reduced energy consumption. Compare the results with expected values based on design specifications.

Durability Testing

Conduct endurance tests by subjecting the bearing to continuous or cyclic loads and speeds over a prolonged period. Assess any changes in performance, such as increased friction, noise, or wear, which could indicate potential issues with quality or design.

Temperature Testing

Monitor the temperature rise of the bearing during operation under load. Excessive heat can indicate inadequate lubrication, misalignment, or internal friction, all of which affect bearing performance and longevity.

Noise and Vibration Analysis

Use specialized equipment to detect and analyze noise and vibration levels during operation. Excessive noise or vibration may indicate defects, misalignment, or improper installation.

Material Analysis

Perform material testing to verify the composition and properties of bearing components, such as steel balls or rollers, cages, and raceways. Ensure they meet specified standards for hardness, strength, and durability.

Overline

Section with image

Overline

Take A Look at Our Factory

In essence, wherever there is a need to support axial loads in rotating machinery, thrust bearings play a critical role in ensuring smooth operation, reducing friction, and extending the lifespan of components.

Send us a message!

You can send us advices, complaints, inquiries, and also make appointments with us to visit the factory!

whatsapp me by