Design and Functionality

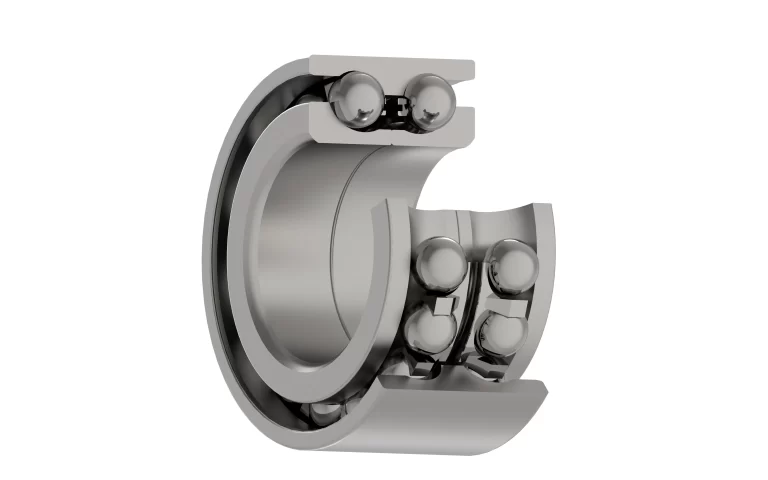

Angular contact ball bearings feature raceways that are designed to support angular misalignment to a certain extent, making them ideal for applications where shaft deflection or misalignment may occur. They typically consist of an inner and outer ring with a set of balls placed between them. The angle between the bearings’ inner and outer rings determines the contact angle, which influences the bearing’s load-carrying capacity and operational characteristics.

High precision

Angular contact bearings are designed for high precision and rigidity, making them suitable for applications requiring exact positioning and smooth operation.

High-speed capability

They can operate at high speeds due to their low friction and optimized design.

Versatility

Available in various sizes and configurations to suit different load and speed requirements.

GET IN TOUCH

Schedule a Visit

These have a single row of balls with a contact angle that allows them to support axial loads in one direction.

Single-row angular contact bearings

These have two rows of balls separated by a spacer, allowing them to support higher radial and axial loads and increased stiffness.

Double-row angular contact bearings

How to tell a good-quality angular contact ball bearing?

Small tips…

1. Visual Inspection

Begin by visually inspecting the bearing for any signs of damage, such as cracks, corrosion, or uneven wear on the raceways and rolling elements. Look for smooth surfaces and consistent dimensions across the bearing components.

2. Measurement of Dimensions

Use precision measuring tools to verify the dimensions of the bearing components, including inner and outer diameters, width, and ball diameter (if applicable). Compare these measurements against the manufacturer’s specifications to ensure they fall within acceptable tolerances.

3. Noise and Vibration Analysis

Rotate the bearing manually or with a testing apparatus and listen for any abnormal noises such as grinding, clicking, or rumbling. Excessive noise can indicate poor quality or damage. Additionally, use vibration analysis tools to measure vibration levels; excessive vibration can indicate misalignment, imbalance, or internal defects.

4. Running Torque Measurement

Measure the running torque of the bearing when rotating at a specified speed. High running torque can indicate excessive friction due to poor lubrication, misalignment, or bearing defects.

5. Load Capacity Testing

Subject the bearing to loads corresponding to its rated capacity to ensure it can withstand the specified radial and axial loads without excessive deformation or damage. Use load-testing equipment to apply controlled loads and measure the bearing’s response.

6. Temperature Rise Test

Run the bearing at a specified speed and load for a period while monitoring the temperature rise. Excessive temperature rise can indicate frictional heating due to poor lubrication or bearing misalignment.

7. Lubrication Evaluation

Check the condition of the lubricant and verify that it meets the manufacturer’s recommendations. Proper lubrication is critical for reducing friction and wear, enhancing bearing life and performance.

8. Endurance and Life Testing

Perform endurance testing by subjecting the bearing to continuous operation under specified conditions (speed, load, and temperature) for an extended period. Monitor performance parameters such as noise, vibration, temperature rise, and running torque to assess long-term reliability.

9. Supplier and Certification

Ensure that the bearing comes from a reputable supplier and meets industry standards (e.g., ISO, ABEC). Look for certifications or quality assurance marks indicating compliance with international standards for bearing manufacturing and performance.

Overline

Take A Look At Our Angular Contact Ball Bearing

Angular contact ball bearings play a crucial role in modern machinery and equipment, offering high precision, reliability, and versatility in handling combined axial and radial loads. Their design and functionality make them indispensable in industries where performance, efficiency, and durability are paramount. As technology advances, these bearings continue to evolve, meeting the demands of increasingly complex applications across diverse sectors.

Send us a message!

You can send us advices, complaints, inquiries, and also make appointments with us to visit the factory!

whatsapp me by