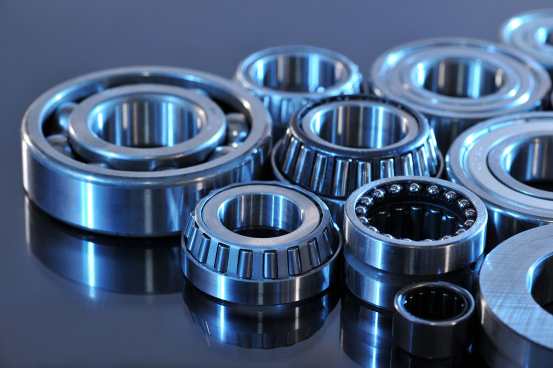

Bespoke Bearings

For small factory like us, we are very feasible at bespoke bearings, especially

for projects under trial stages, we are able to support with samples, and the

quantity requirement varies from 2pcs to 20pcs.

Production Flow Chart of Bearing Customization

Each of these steps can be further detailed depending on the specific requirements of the customized bearing and the manufacturing capabilities of the company. The flow chart visually represents these steps in sequential order, illustrating how materials and information flow through each stage of production until the final product is ready for delivery to the customer.

Customer Requirements Analysis

Synergestic actionables. Organic growth deep dive but circle back or but what’s the real problem we’re trying to solve here?

Design Phase

The customer can either come with drawings or detailed requirements. We are able to analyze and transform rough drawings, design a set of drawings based on requirements and parameters given.

Material Preparation

Cut raw materials into appropriate lengths (for rings) or strips (for cages and rolling elements). In China, due to benefits from the industrial agglomeration effect, normally manufacturers purchase the rings and strips directly.

Forging or Turning

Shape the rough form of bearing rings through forging process; Machine the rough material into preliminary shapes of inner and outer rings.

Heat Treatment

Heat rings to remove internal stresses and refine grain structure; Achieve desired hardness and toughness for load-bearing capabilities by hardening and tempering.

Turning and Grinding

Achieve final dimensions and smooth surface finish by precision turning; Further refine surface finish and accuracy by grinding.

Assembly

Assembly of components (inner ring, outer ring, rolling elements, and cage). Press fitting or other methods to secure components together.

Lubrication

Apply lubricant to rolling elements and inner/ outer rings to reduce friction and wear.

Testing & Inspection

Dimensional inspection: Verify dimensions and tolerances.Performance testing: Conduct functional tests such as noise, vibration, and rotation under load.

Advantages

Why we can be so confident?

Accuracy

Accuracy can be controlled within the designed tolerance. We have opened up the upstream and downstream of the whole production line from material, heat treatment, carburization, etc. Without debts caused by expensive heat treatment equipment, we are able to give reasonable prices.

Quality Warranty

Accurate processing ensures the the bearings are of low noise as operation. As the outer/inner ring OEM supplier for some famous brands in Dalian, Luoyang, some of our products on shelf are jointly produced products. We welcome wholesalers or distributors to test our sample bearings.

Complete Processing flow

A complete and standard processing flow is vital for quality. Limited by technology and various machines, processing accuracy is hard to be controlled if we only take turning or lathing, the rough grinding and fine grinding are neglected by some factories due to cost-saving purpose.

Overline

Have A Look at Bespoke Bearings

Unlike standard bearings, which adhere to industry-standard dimensions and designs, non-standard bearings are tailored to specific needs such as miniature dimensions, custom load capacities, or unusual operating conditions. These bearings are typically crafted through precise engineering and manufacturing processes to ensure optimal performance in diverse and sometimes challenging environments.

Send us a message!

You can send us advices, complaints, inquiries, and also make appointments with us to visit the factory!

whatsapp me by