How to tell A Good Quality Roller Bearing

Assessing the quality of a roller bearing involves looking at its material quality, precision manufacturing, lubrication, load capacity ratings, sealing/shielding, noise/vibration levels, durability, adherence to standards, supplier reputation, and suitability for your specific application. These factors collectively help determine whether a roller bearing will deliver reliable performance and longevity in its intended use.

We are great at manufacturing TBM tapered roller bearings, and four-row cylindrical roller bearings for rolling mills. Our bearings currently have indirectly served in some national projects and mining equipment factories.

You may send us the basic information of the bearings you demand for such as dimensions or model numbers, to check if we have in stock.

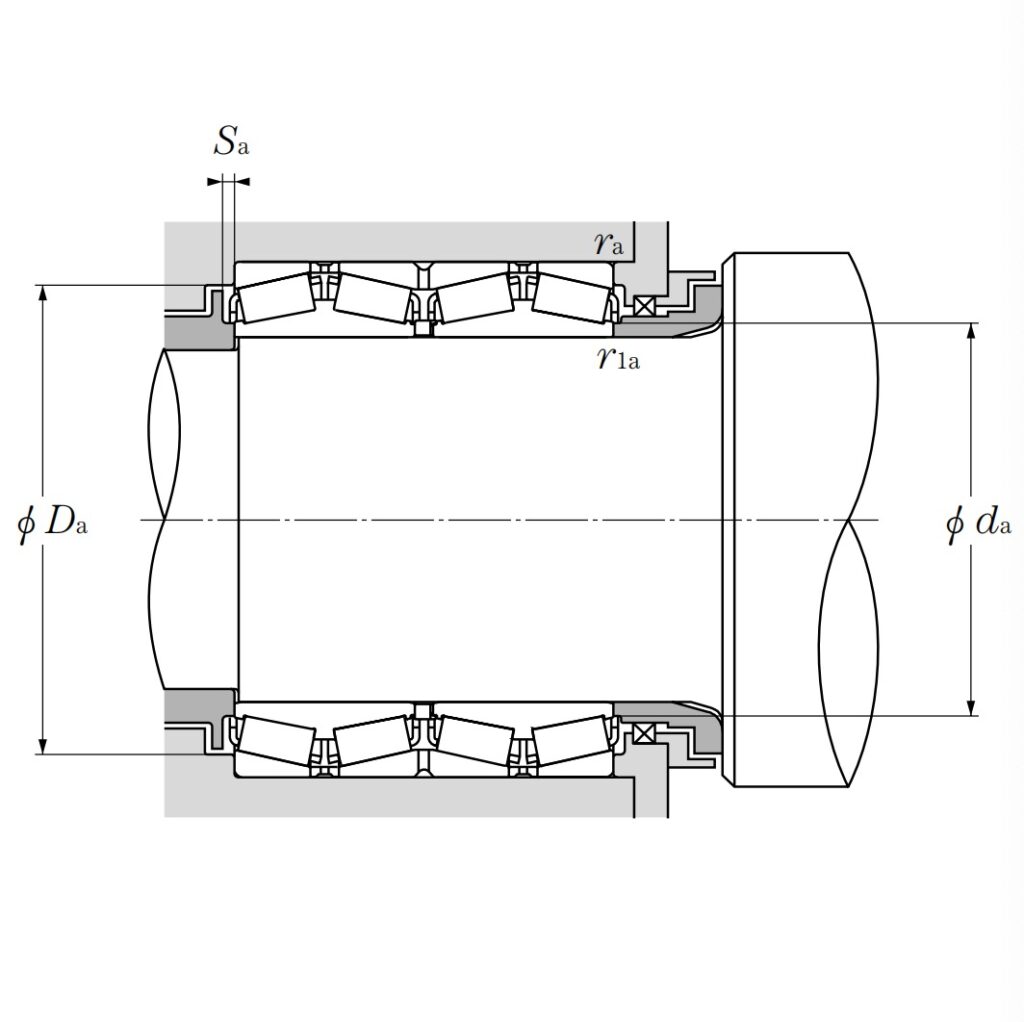

Product Drawing

Small Tips on Roller Bearing Selection

Material Quality

Sed ut perspiciatis unde omnis natus error sit voluptatem accusantium doloremque.

Lubrication

Sed ut perspiciatis unde omnis natus error sit voluptatem accusantium doloremque.

Precision Manufacturing

Sed ut perspiciatis unde omnis natus error sit voluptatem accusantium doloremque.

Sealing and Shielding

Sed ut perspiciatis unde omnis natus error sit voluptatem accusantium doloremque.

Load Capacity and Performance

Dynamic Load Rating: Indicates the maximum load a bearing can withstand while rotating at a specific speed without premature fatigue; Static Load Rating: Indicates the maximum load a bearing can support without permanent deformation.

Warranty

Bearings from reputable manufacturers or brands with a history of producing reliable products tend to offer better durability and longer service life.

Noise and Vibration Levels

Low noise and vibration levels during operation indicate smoother running and reduced wear, which are characteristic of high-quality bearings.

Applications

Consider whether the bearing is designed and rated for the specific conditions of your application, such as temperature extremes, high speeds, or heavy loads.

Overline

Taper/Cylindrical Roller Bearing

Our selling point is that we stady and take SKF Processing Standards.

Overline

Taper/Cylindrical Roller Bearings

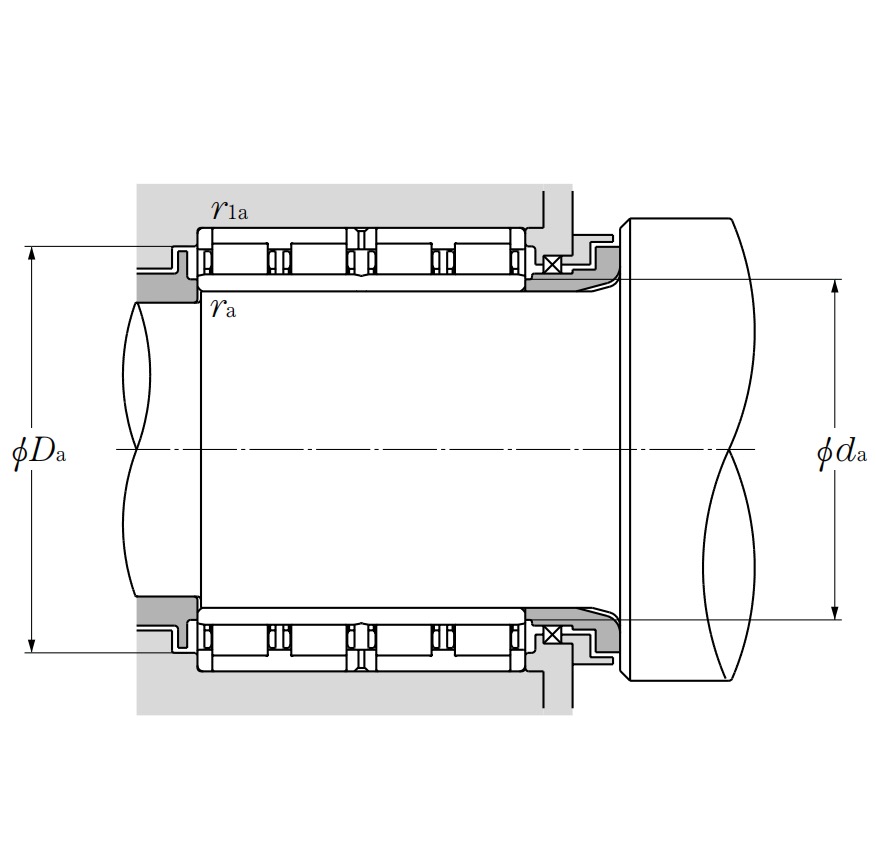

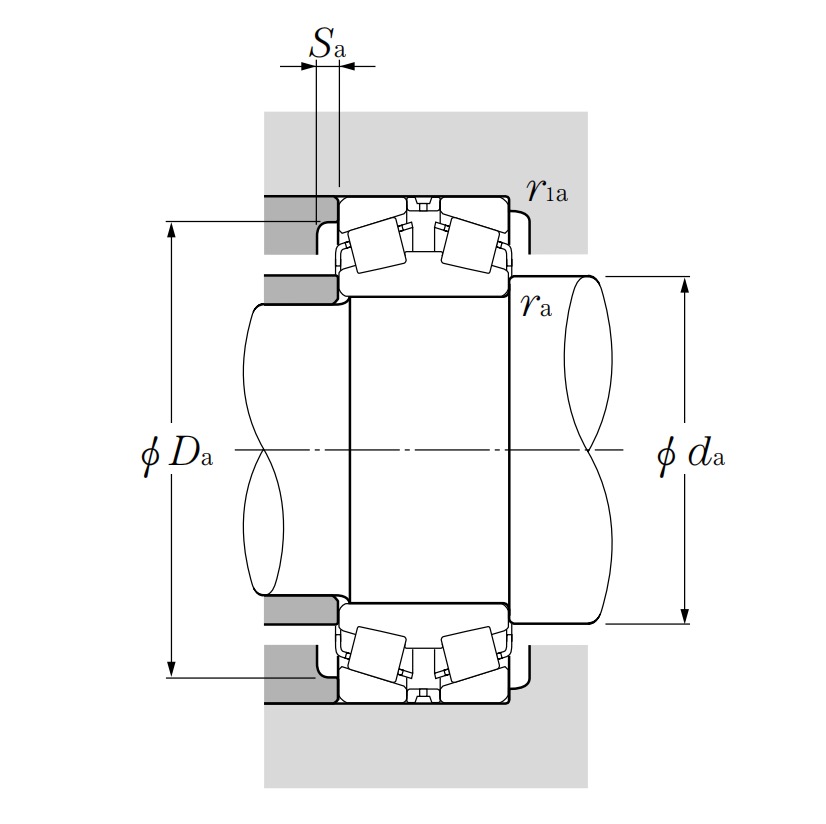

Taper Roller Bearings are designed to handle both radial and axial loads, thanks to their unique tapered shape. These bearings consist of an inner ring, outer ring, and tapered rollers arranged in a conical shape, allowing them to efficiently manage combined loads in multiple directions. Their design makes them ideal for applications requiring high load capacity and durability, such as automotive wheel hubs, gearboxes, and heavy machinery.

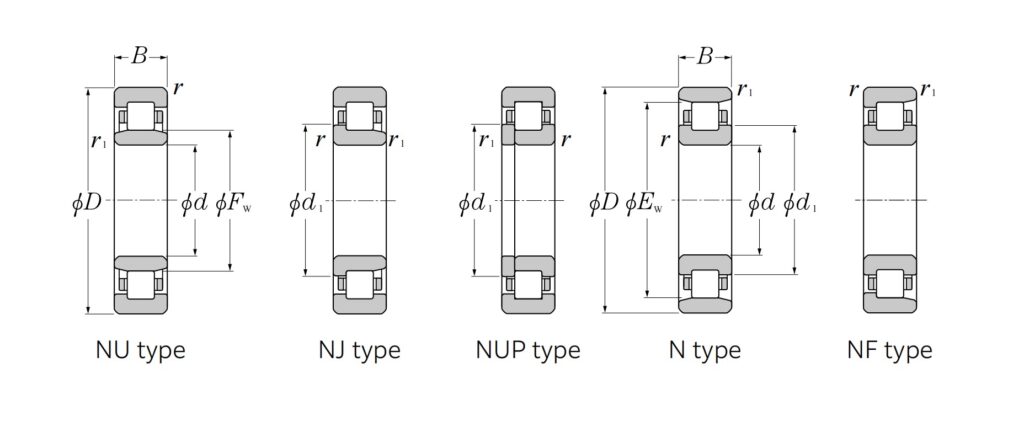

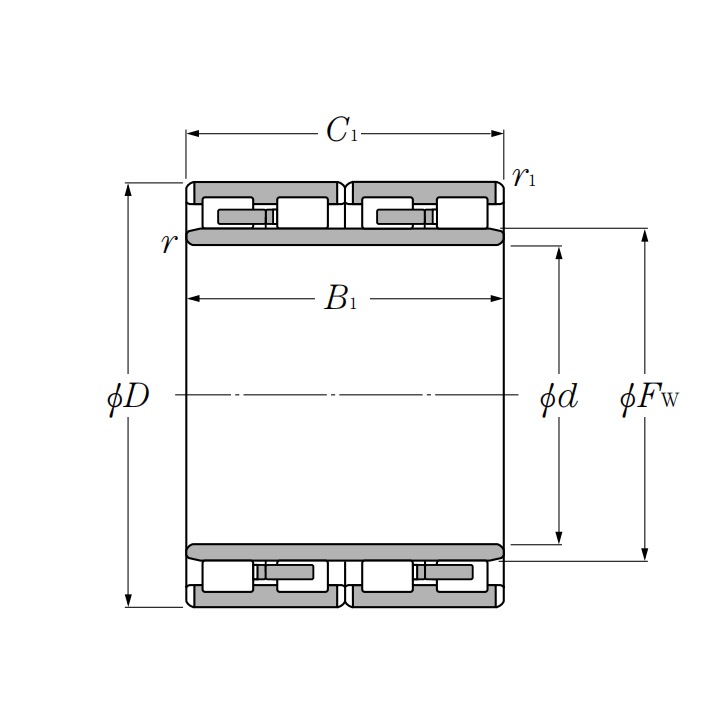

On the other hand, Cylindrical Roller Bearings are engineered to support heavy radial loads while maintaining high-speed performance. Composed of cylindrical rollers and raceways, these bearings provide minimal friction and high precision, making them suitable for applications where low noise and high rotational speed are crucial. Industries such as electric motors, turbines, and large-scale industrial equipment commonly rely on cylindrical roller bearings for their robustness and reliability.

Send us a message!

You can send us advices, complaints, inquiries, and also make appointments with us to visit the factory!

whatsapp me by